Marques Brownlee was given an inside look at how Apple torture tests its iPhones and other products in its labs, ranging from IP testing, shaking, and dropping.

Apple Labs is where the tech giant performs a host of tests to assure product durability over the long term. It’s also where Apple tests a product’s resilience to earn specific ratings, such as the IP68 that the iPhone 15 Pro Max has. As Brownlee explains in a thread on X (formerly Twitter), IP ratings are very specific.

“Level 1: A drip tray simulating rain, no real pressure. IPX4. Level 2: A sustained, low-pressure jet spray from any angle. IPX5. Level 3: High pressure spray from a literal firehose. IPX6. Level 4: Locking the phone underwater + added pressure to simulate depth for an extended time. IPX8,” he writes.

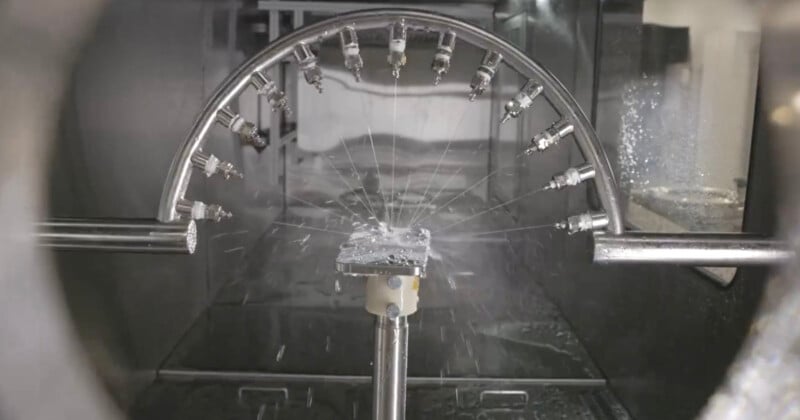

While the description of how IP is rated is the same across products, how a company might test them varies. For example, Apple’s spray test machine, below, uses an arch of nozzles that is moved over the iPhone.

I recently got to visit some Apple labs where they durability test new iPhones before they come out, and learned a few things (🧵THREAD)

#1: Have you actually seen how they water test phones for IP ratings? (video) pic.twitter.com/Qh3hfmlmdn

— Marques Brownlee (@MKBHD) May 29, 2024

While OM System, which is the only camera company that makes interchangeable lens cameras with an IP rating, uses a different machine with more moving parts, as seen below and in more detail in a feature story from 2022.

![]()

Water testing is just one aspect of what Apple does. As shown by Brownlee, the company also has an industrial robot that simulates different drop angles onto various surfaces. Apple captures footage of these drops in super slow motion so that it can better evaluate how its products handle the impacts.

#3: Apparently Apple has also bought and programmed and industrial robot to be their own drop test machine – to simulate hundreds of different drop angles onto different materials

Then they hit it with some ultra bright lights and a high speed camera to watch them back in… pic.twitter.com/EsNJbVQrbO

— Marques Brownlee (@MKBHD) May 29, 2024

Beyond that, Apple also tests products for how they handle shaking. A large machine is able to simulate how something, like the Vision Pro, is able to withstand sustained exposure to a specific frequency.

#4 Ok this one was hard to capture on camera – it’s literally shaking everything at computer-controlled frequencies. They can program in the frequency of a certain motorcycle engine or subway car to simulate how well a device will hold up to sustained exposure to that frequency… pic.twitter.com/K981NzQhhk

— Marques Brownlee (@MKBHD) May 29, 2024

Brownlee also sat down and spoke with Apple’s Head of Hardware Engineering John Ternus, who explained how Apple balances two ends of a particular spectrum: a product that is so durable it can last forever versus one that is easily repairable but therefore does not last as long. It is one reason that Apple presents as to why it has historically been resistant to repair initiatives regarding its devices.

“I find it helpful to kind of think about the bookends. If you imagine a product that never fails, that just doesn’t fail, and on the other end a product that maybe isn’t very reliable but is super easy to repair, right? Product that never fails is obviously better for the customer. It’s better for the environment,” Ternus says.

“I think a battery on an iPhone is being an important one… if you want to extend the life of the product, that’s something that’s going to need to be replaced, right? Batteries wear out. But as we’ve been making iPhones for a long time, in the early days, one of the most common types of failures was water ingress, where you drop it in a pool or you spill your drink on it and the unit fails. And so we’ve been making strides over all those years to get better and better and better in terms of minimizing those failures. And I don’t know how many years it’s been now, but we got to a point of IP68, which is kind of a rating for water ingress, which is really impressive,” he continues.

#6 Thankfully Apple is still softening their stance on repair – basically sliding slightly on that durability vs repairability spectrum pic.twitter.com/OA3f4JeOQe

— Marques Brownlee (@MKBHD) May 29, 2024

Ternus points to an anecdote about a customer who dropped their iPhone in a lake and didn’t fish it out for two weeks — it still worked.

“To get the product there, you’ve got to design a lot of seals, adhesives, other things to make it perform that way, which makes it a little harder to do that battery repair. You still need to do the battery repair, so we need to make sure we have solution for customers to do that — which we do, but it’s objectively better for the customer to have that reliability, and it’s ultimately better for the planet because the failure rates, since we got to that point, have just dropped,” Ternus argues.

#7: Connecting the durability test machines the real world: They may test 10,000+ pre-release phones while testing before the phone comes out pic.twitter.com/8JbhMXEPdY

— Marques Brownlee (@MKBHD) May 29, 2024

“It’s plummeted the number of repairs that need to happen, and every time you’re doing a repair, you’re bringing in new materials to replace whatever broke. So you can actually do the math and figure out there’s a threshold at which if I can make it this durable, then it’s better to have it a little bit harder to repair because it’s going to net out.”

The conversation, which is broken up between three short video clips, is unusually candid for one involving Apple and is certainly worth watching for those who want a bit more insight into how a company like Apple thinks.

Image credits: Header image is a screenshot from a video shared by Marques Brownlee.