Traditionally, in India, alcohol is produced mainly from sugarcane which yields only 6-8% alcohol, necessitating imports from China.

The research into the new technique will be published in the Scientific Reports journal by Nature, and a patent is being filed. Mehtab and Aziz said India produced 230 crore tonnes of agricultural waste in 2021 and 750 tonnes in 2023. This biomass, containing 70-90% sugar polymers (cellulose), is suitable for bioethanol (alcohol) production.

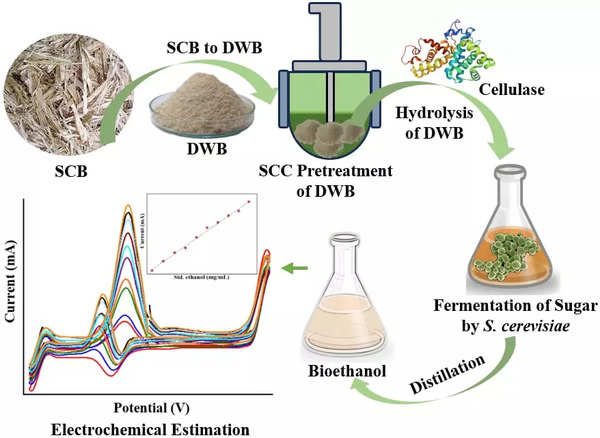

Despite abundant biomass, India produces only about 15% of its bioethanol consumption, using only edible sugar. China developed bioethanol-from-biomass technology long ago but has not shared it. Most countries rely on fermentation technology for bioethanol production. In traditional fermentation, cellulose is extracted from biomass, fermented with enzymes to produce sugar, vapourised, isolated, and fermented again to produce 6-8% alcohol. The new technology avoids using organic solvents, which would render the alcohol unusable.

The new method involves isolating cellulose from sugarcane bagasse or other high-cellulose waste, incubating it to produce fermentable sugar, and then hydrolysing it with an enzyme in a solvent. This swells the biomass and allows the enzyme to penetrate deeply. Unlike the old method, which only converts the surface carbohydrates, this technique ensures a more thorough conversion.

Prof Zaidi said, “We developed a technology to produce alcohol from agricultural waste after nearly a decade of hard work. China produces and exports alcohol from agricultural waste at low prices, while in India, alcohol from sugarcane is nearly six times more expensive due to its low yield.”