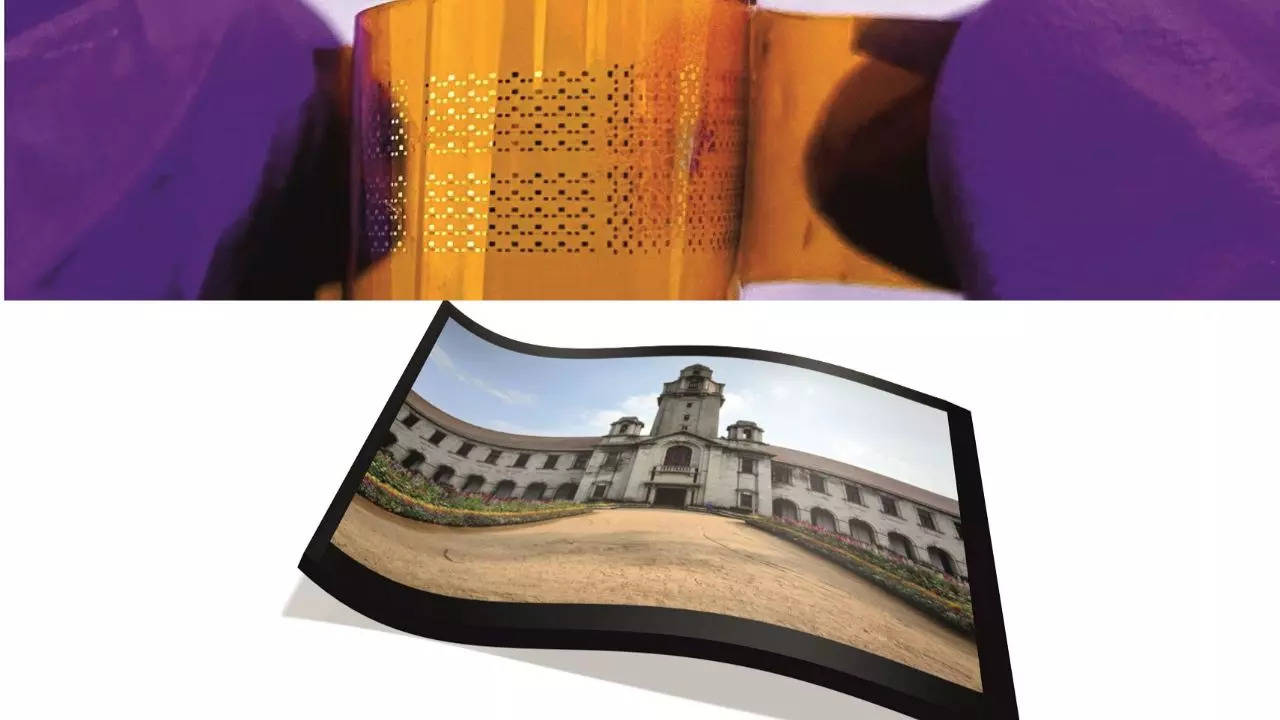

Scientists at IISc’s department of materials engineering (DME) have developed a super flexible, composite semiconductor material that can have possible applications in next-generation flexible or curved displays, foldable phones and wearable electronics.

Traditional semiconductor devices — such as transistors, the building blocks of most electronic circuits — used in display industries are either made of amorphous silicon or amorphous oxides, both of which are not flexible and strain tolerant at all, IISc said in a statement.

It added that adding polymers to oxide semiconductors may increase flexibility, but there’s a limit to how much can be added without compromising the semiconductor’s performance.

“In the current study, published in Advanced Materials Technologies, researchers found a way to fabricate a composite containing a significant amount of polymer – up to 40% of the material weight – using a solution-process technique, specifically inkjet printing. In contrast, previous studies have reported only up to 1-2% polymer addition,” the statement read.

“…Interestingly, the approach enabled semiconducting properties of the oxide semiconductor to remain unaltered with polymer addition. The added large quantity of polymer also made the composite semiconductor highly flexible and foldable without deteriorating its performance,” it added.

The composite semiconductor is made up of two materials: A water-insoluble polymer such as ethyl cellulose that provides flexibility, and indium oxide, a semiconductor which brings in excellent electronic transport properties.

“To design the material, researchers mixed polymer with the oxide precursor in such a way that interconnected oxide nanoparticle channels are formed (around phase-separated polymer islands) through which electrons can move from one end of a transistor (source) to the other (drain), ensuring a steady current flow,” IISc said.

The key to form these connected pathways, researchers found, was the choice of the right water-insoluble polymer that doesn’t mix with oxide lattice when oxide semiconductor is being fabricated.

“This ‘phase separation’ and the formation of polymer-rich islands helps in crack arrest, making it super flexible,” says Subho Dasgupta, associate professor in the department of materials engineering, and corresponding author of the study.

Semiconductor materials are usually fabricated using deposition techniques such as sputtering. Instead, Dasgupta’s team uses inkjet printing to deposit material onto various flexible substrates ranging from plastics to paper.

“In the study, a polymer material called Kapton has been used. Just like words and images printed on paper, electronic components can be printed on any surface using special functional inks containing either electrically conducting, semiconducting or insulating materials. However, there are challenges,’ IISc said.

“Sometimes it is very difficult to get continuous and homogeneous film. Therefore, we had to optimise certain protocols, for example, preheating printed semiconductor layer on Kapton substrate prior to high temperature annealing,” first author Mitta Divya, former PhD student at DME and currently a postdoc at King Abdullah University of Science and Technology (KAUST), Saudi Arabia, said.

Another challenge is ensuring the right environmental conditions under which ink can be printed. “If humidity is too low, you can’t print, because the ink dries up within the nozzle,” says Dasgupta, adding that in the future, such printed semiconductors can be used to fabricate fully printed and flexible television screens, wearables, and large electronic billboards alongside printed organic light emitting diode (OLED) display front-ends.

Traditional semiconductor devices — such as transistors, the building blocks of most electronic circuits — used in display industries are either made of amorphous silicon or amorphous oxides, both of which are not flexible and strain tolerant at all, IISc said in a statement.

It added that adding polymers to oxide semiconductors may increase flexibility, but there’s a limit to how much can be added without compromising the semiconductor’s performance.

“In the current study, published in Advanced Materials Technologies, researchers found a way to fabricate a composite containing a significant amount of polymer – up to 40% of the material weight – using a solution-process technique, specifically inkjet printing. In contrast, previous studies have reported only up to 1-2% polymer addition,” the statement read.

“…Interestingly, the approach enabled semiconducting properties of the oxide semiconductor to remain unaltered with polymer addition. The added large quantity of polymer also made the composite semiconductor highly flexible and foldable without deteriorating its performance,” it added.

The composite semiconductor is made up of two materials: A water-insoluble polymer such as ethyl cellulose that provides flexibility, and indium oxide, a semiconductor which brings in excellent electronic transport properties.

“To design the material, researchers mixed polymer with the oxide precursor in such a way that interconnected oxide nanoparticle channels are formed (around phase-separated polymer islands) through which electrons can move from one end of a transistor (source) to the other (drain), ensuring a steady current flow,” IISc said.

The key to form these connected pathways, researchers found, was the choice of the right water-insoluble polymer that doesn’t mix with oxide lattice when oxide semiconductor is being fabricated.

“This ‘phase separation’ and the formation of polymer-rich islands helps in crack arrest, making it super flexible,” says Subho Dasgupta, associate professor in the department of materials engineering, and corresponding author of the study.

Semiconductor materials are usually fabricated using deposition techniques such as sputtering. Instead, Dasgupta’s team uses inkjet printing to deposit material onto various flexible substrates ranging from plastics to paper.

“In the study, a polymer material called Kapton has been used. Just like words and images printed on paper, electronic components can be printed on any surface using special functional inks containing either electrically conducting, semiconducting or insulating materials. However, there are challenges,’ IISc said.

“Sometimes it is very difficult to get continuous and homogeneous film. Therefore, we had to optimise certain protocols, for example, preheating printed semiconductor layer on Kapton substrate prior to high temperature annealing,” first author Mitta Divya, former PhD student at DME and currently a postdoc at King Abdullah University of Science and Technology (KAUST), Saudi Arabia, said.

Another challenge is ensuring the right environmental conditions under which ink can be printed. “If humidity is too low, you can’t print, because the ink dries up within the nozzle,” says Dasgupta, adding that in the future, such printed semiconductors can be used to fabricate fully printed and flexible television screens, wearables, and large electronic billboards alongside printed organic light emitting diode (OLED) display front-ends.

Denial of responsibility! Swift Telecast is an automatic aggregator of the all world’s media. In each content, the hyperlink to the primary source is specified. All trademarks belong to their rightful owners, all materials to their authors. If you are the owner of the content and do not want us to publish your materials, please contact us by email – swifttelecast.com. The content will be deleted within 24 hours.