Titanium (Ti), often hailed as the wonder metal for its remarkable properties, has many applications in aerospace, marine, and biomedicine industries. Known for their low density, high strength, high ductility, great corrosion resistance, and excellent biocompatibility, Ti and its alloys have been widely studied by numerous researchers for their structural deformation mechanisms at room temperatures.

Recently, researchers have focused their efforts on studying the deformation of Ti and its alloys at very low “cryogenic” temperatures (< 77K, the temperature of liquid nitrogen).

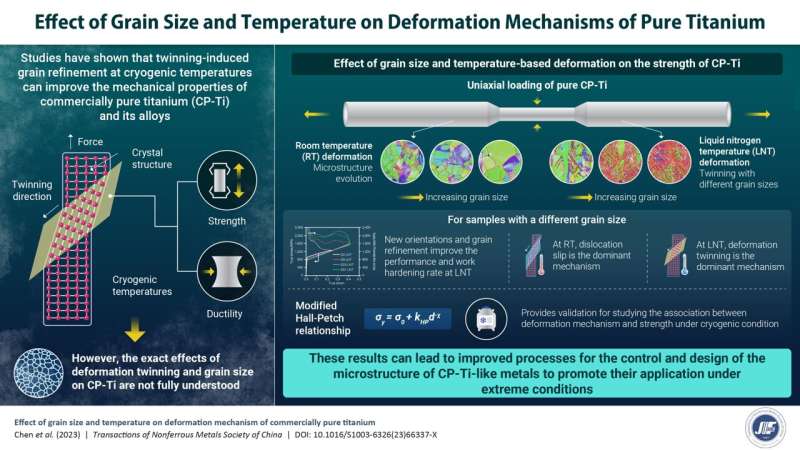

Ti and its alloys deform via different mechanisms, including dislocation slips, in which grains of metals slip over each other, and “deformation twinning,” wherein the grains arrange symmetrically around a common grain boundary. A grain, namely a well-defined region within a crystalline material, consists of atoms arranged in a specific, consistent way. The occurrence of deformation twins in Ti alloys depends on the initial texture, strain rate, deformation temperature, and grain size.

Studies have shown that twinning can improve the mechanical properties of materials. Furthermore, cryogenic deformation of commercially pure Ti (CP-Ti) has been shown to trigger deformation twinning, significantly boosting its strength and ductility. However, the exact effects of different deformation mechanisms and grain size on the strength of CP-Ti at cryogenic temperatures have not been fully understood.

To address this gap, a team of researchers from China, led by Assistant Professor Cai Chen and Dr. Ji-zi Liu from Nanjing University of Science and Technology, investigated the mechanical properties and twinning behavior of CP-Ti at room temperature and liquid nitrogen temperature (LNT).

“Studying the deformation behavior of CP-Ti and its alloys at cryogenic temperatures can help in the development of new controlled processes for improving their strength and ductility,” explains Dr. Chen. Their paper was published in the journal Transactions of Nonferrous Metals Society of China.

Using advanced techniques such as scanning electron backscatter diffraction and transmission electron microscopy, the researchers studied changes in the microstructure and dislocations of the CP-Ti samples under uniaxial loading at both temperatures. They investigated plastic hardening behavior, twinning-induced grain fragmentation, texture transformation, and plasticity of the samples.

Their experiments revealed that the recrystallized samples deformed at LNT exhibited a much better combination of strength and ductility than those deformed at room temperature. Moreover, the sample with the smallest grain size at both temperatures showed the highest yield strength.

Dislocation slip was identified as the main deformation mechanism at room temperature, while deformation twinning became dominant at LNT. This transition of deformation mechanisms emerged as the main contributing factor to the outstanding mechanical properties observed at LNT. Furthermore, the team also proposed a modified Hall-Petch relationship accounting for cryogenic temperatures to explain the strengthening mechanism.

Dr. Liu says, “The results of the study provide important insights into the deformation processes of hexagonal metals at cryogenic temperatures. This can lead to improved processes for control and design of the metals that can withstand extreme conditions.”

Overall, this study enhances our understanding of the microstructure and deformation mechanisms of metals like Ti and paves the way for the development of stronger and more ductile metals.

More information:

Cai Chen et al, Effect of grain size and temperature on deformation mechanism of commercially pure titanium, Transactions of Nonferrous Metals Society of China (2023). DOI: 10.1016/S1003-6326(23)66337-X

Provided by

Cactus Communications

Citation:

Study uncovers low-temperature deformation mechanism of pure titanium (2024, January 10)

retrieved 10 January 2024

from https://phys.org/news/2024-01-uncovers-temperature-deformation-mechanism-pure.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.