Polyurethane is highly elastic, wear resistant and durable, and is used, for example, in cushions, fibers, thermal insulation materials, dyes, adhesives and automobile parts. Polyurethane is an industrially-important polymer material, with an estimated worldwide market value of 75 billion dollars.

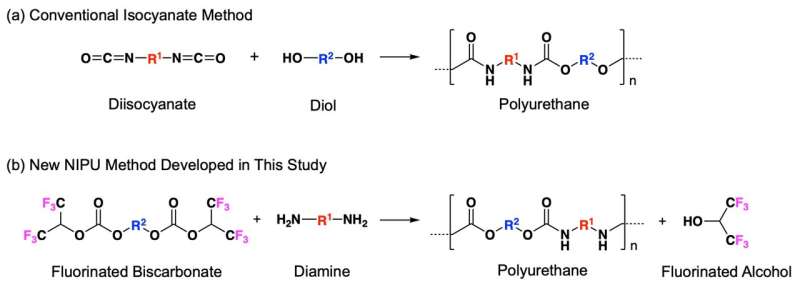

Most polyurethane is currently synthesized by means of reacting diisocyanate with diol. However, isocyanate compounds are highly toxic, and the tightening of regulations on the use of diisocyanate are progressing recently, particularly in the EU, because of health and environmental concerns. In recent years, active research is proceeding into the synthesis of polyurethane without using isocyanate compounds with a view to implementing a sustainable society.

However, most current methods are not practicable because of the variety of problems associated with them: They have low utility as well as high environmental costs, and the quality of the derived polyurethane is low as well as being expensive.

Against this backdrop, Kobe University Associate Professor Tsuda and AGC, combined their efforts to jointly develop a novel polyurethane synthesis method. University-industry cooperation between the research group of Associate Professor Tsuda, pioneers of the Photo-on-demand organic synthesis method and AGC, a manufacturer of fluorinated compounds and polyurethane raw materials, created a new academic field and industrial activity based on the development of a new polyurethane synthesis method and functional materials.

Content of the research

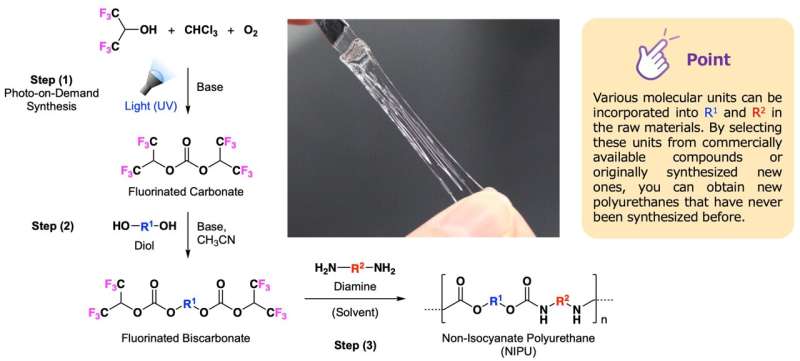

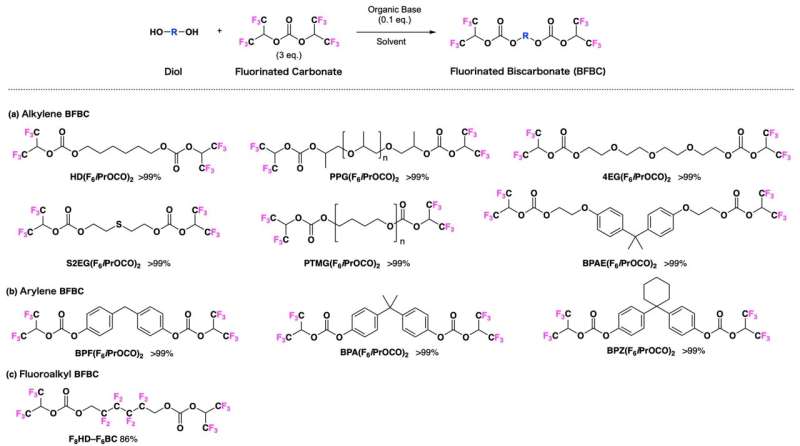

A variety of fluorinated biscarbonates (BFBC) were synthesized by a condensation reaction of fluorinated carbonates, synthesized in the photo-on-demand synthesis method from fluorinated alcohols and chloroform, with diols. The BFBC generated could be purified by merely drying the derived sample solution at reduced pressure, enabling the quantitative derivation of the target substance by a simple operation.

The synthesis of a non-isocyanate polyurethane (NIPU) with an average molecular weight in excess of 10,000 was achieved by polycondensation of the derived BFBC with diamine. The NIPU synthesized without solvent was only slightly discolored at over 120°C, and that discoloration was not observed up to 100°C. On the other hand, if a solvent is used, it can be polymerized at a lower temperature, and a high molecular weight colorless NIPU is derived at a high-yield.

They were able to form a highly-elastic colorless and transparent polyurethane by an appropriate combination of BFBC and diamines in hard and soft segments. They also succeeded in synthesizing a novel fluorinated polyurethane which is a colorless transparent oil.

The variety and types of polyurethane synthesized, with a range from general purpose to specific applications, have the following benefits when compared to the previously reported synthesis methods of NIPU:

- Any NIPU can be synthesized which employs commercially available diols or diamines employed in the industrial manufacture of polyurethane by the isocyanate method, or which was originally used in the synthesis of NIPU.

- This is a synthesis method which does not use organic bases, metallic catalysts or solvents in the synthesis, such that a high quality NIPU can be derived which does not contain any of them.

- The average molecular weight and terminal functional groups can be controlled by the admixture ratio of BFBC and the diamines. An NIPU prepared by this method with the molecular weight of the order of 10,000 can be employed as a prepolymer in order to synthesize even larger polymers or network

Denial of responsibility! Swift Telecast is an automatic aggregator of the all world’s media. In each content, the hyperlink to the primary source is specified. All trademarks belong to their rightful owners, all materials to their authors. If you are the owner of the content and do not want us to publish your materials, please contact us by email – swifttelecast.com. The content will be deleted within 24 hours.