While the company might be producing a variety of products, Shirodkar said that even today, the automotive business tends to contribute a large share of the entire company’s revenue. With the entire industry experiencing an electrified transformation, 3M is also armed with solutions for the new challenges brought about by electrification.

TOI Auto car vlog: Is Tata Tiago EV still best value for money? | TOI Auto

The challenges of working with EVs

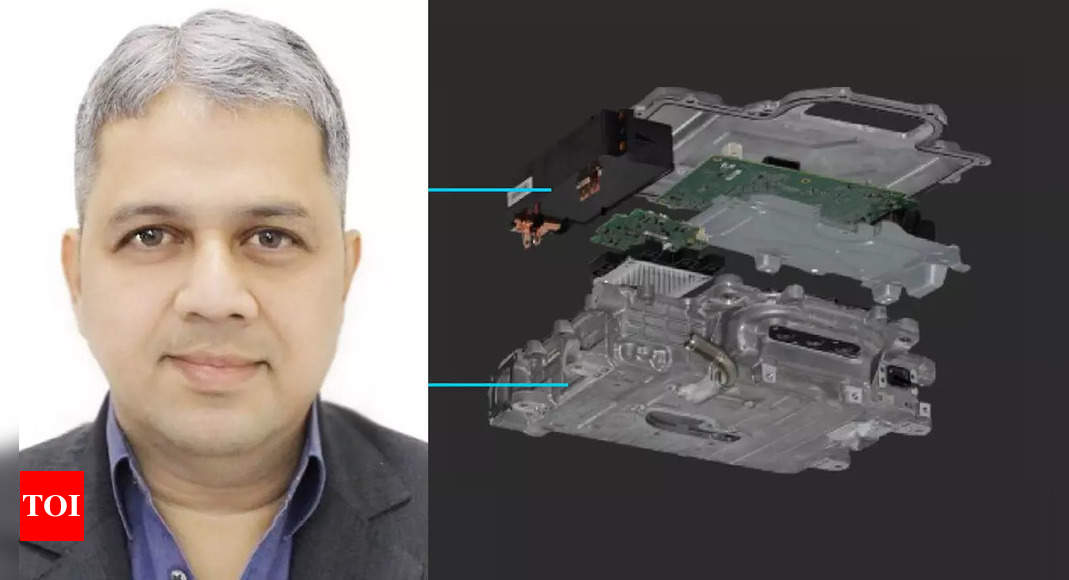

Shirodkar told us that 3M has been closely working with the automotive industry as it transitions from being driven by fossil fuel-powered vehicles to electrified ones. Be it hybrid vehicles or fully electric ones, both have to navigate around the same issue – how do you put the maximum amount of energy in the minimum amount of space? Apart from this, it has to be ensured that lithium-ion batteries, which employ exothermic chemistry, are safe for use. Lastly, there is also the concern of using dissimilar materials without any major problems. When you use dissimilar materials, the chances of galvanic corrosion become higher.

Dealing with insulation

“Creating reliable and large power EV batteries is currently heavily dependent on containing electrical charge.” Shirodkar further told us that 3M is working closely with many major automotive players, including international brands that are yet to enter into the EV space in India, “The one voice that we heard consistently was that putting charge in a compact volume is not as big a concern as is storing it efficiently. Herein, I refer to insulation because we are looking at an explosive charge.” By providing good insulation the heat transfer in the battery can be greatly minimised. To this end, 3M has introduced an inorganic insulation paper which is clay-based and flexible. This insulation paper can withstand surface temperatures of at least 1,000 degrees Celsius or higher. Being inorganic, this paper does not burn or become oxidised. In contrast, Shirodkar told us that the solutions used in the industry had been aramid-based which is a synthetic fibre. This material would usually start to degrade and decompose around 350 degrees Celsius, which is much lower than the threshold for the inorganic material used by 3M.

Reflecting on the safety aspect of EVs, Shirodkar said, “We’ve seen unfortunate incidents, especially in two-wheelers, where batteries have exploded and caught fire, putting at risk not just the vehicle but even the passengers. This is primarily on account of the thermal runaway in these electric vehicles or their batteries. And the cause can be either electrical, thermal or even mechanical damage.” He explained how the materials used by 3M can bring down the heat transmission and even act as a rupture layer. This helps compartmentalise the battery and contain the explosion within the battery.

Bonding matters

The need to bond dissimilar materials has always been there in the automotive industry. In fact, 3M has expertise in making bonding solutions that are used by some of the major smartphone manufacturers. The thickness of these adhesives can be measured in microns. Shirodkar explained, “Not only does it provide a barrier between these two dissimilar materials, not giving any physical connection that can allow for a dielectric coefficient or dielectric corrosion, but also provides impact resistance. These bonding technologies that we use, some of them can expand to 300% of the thickness that they are supplied in and in doing so can absorb impact in a very significant way.” He continued to say, “Now this becomes very, very important in a moving part like an EV battery, especially now that we are looking at vehicles covering terrains that may not always have the most uniform driving conditions.”

EV penetration in the coming years

“The transportation industry accounts for approximately one-quarter of all energy-related greenhouse gas emissions. That has really steered the demand for electric vehicle adoption, globally as well as in India”, said Shirodkar. He talked about how proud he is to say that India has made great strides in terms of its emission goals. There has been a huge push for the adoption of electric vehicles due to their zero tailpipe emission. The government has introduced many incentives for buying EVs and exemptions to reduce their initial purchase cost. Even the commercial transportation sector has seen a significant penetration of electric vehicles.

Shirodkar also touched upon the future of EVs in India and the government’s goals for the same, “The outlook, at least till 2030, is to have around 30% EV penetration for passenger cars.” He also stated that in India, almost 70 to 80% of commercial vehicles could be electrified while the figure will be 80% for two and three-wheelers. The reason for the conservative 30% figure for passenger cars is because of the large distance that is still left to cover. Industry players are still looking at ways to make energy-dense solutions. On top of this, the cost differential between an electric vehicle and a conventional one is still significant. This aspect does stand true in light of the recent reduction in the FAME-II subsidy and subsequent hit to sales.

The role of hybrids

Shirodkar continued to say, “This is where I personally see that this 30% EV penetration that the government has in mind for the mid-range passenger vehicles, will be largely fulfilled through hybrid. That’s primarily because of the fact that using dual-mode reduces the need for higher energy charge density.” Thus, hybrid vehicles can work with smaller batteries and fall back on petrol in case the battery runs out of juice mid-journey. The charging infrastructure is another challenge in the way of increasing pure electric vehicle penetration. While there has been a positive change in the number of charging stations being planted across the country, there is still a long way to go.

“So, all put together, hybrids are certainly the middle path going forward for the next five to seven years. But you know, I’ve seen technology disrupt and transform at a very rapid rate.” Alternatives to lithium-ion are already being looked at, so if one of the alternatives takes off at a much more rapid rate, things could be very different.

With a prediction of hybrids becoming more popular, Shirodkar does believe that there will be advances in battery technology so that these hybrid vehicles will have longer ranges in EV mode, “Today, the amount of energy you regenerate in a vehicle is far higher than what you are able to store.” The challenge faced by manufacturers today is that the bigger the battery in a hybrid vehicle, the more the customer would want to use it. Strong hybrid vehicles deploy self-charging using explosive regenerative braking. This rapid charging and discharging of the battery necessitate the need for even better insulation. He also believes that as the cost of producing batteries becomes cheaper, there will be a much higher penetration of batteries in smaller vehicles and hybrids.